Punching Tools dittmanntools

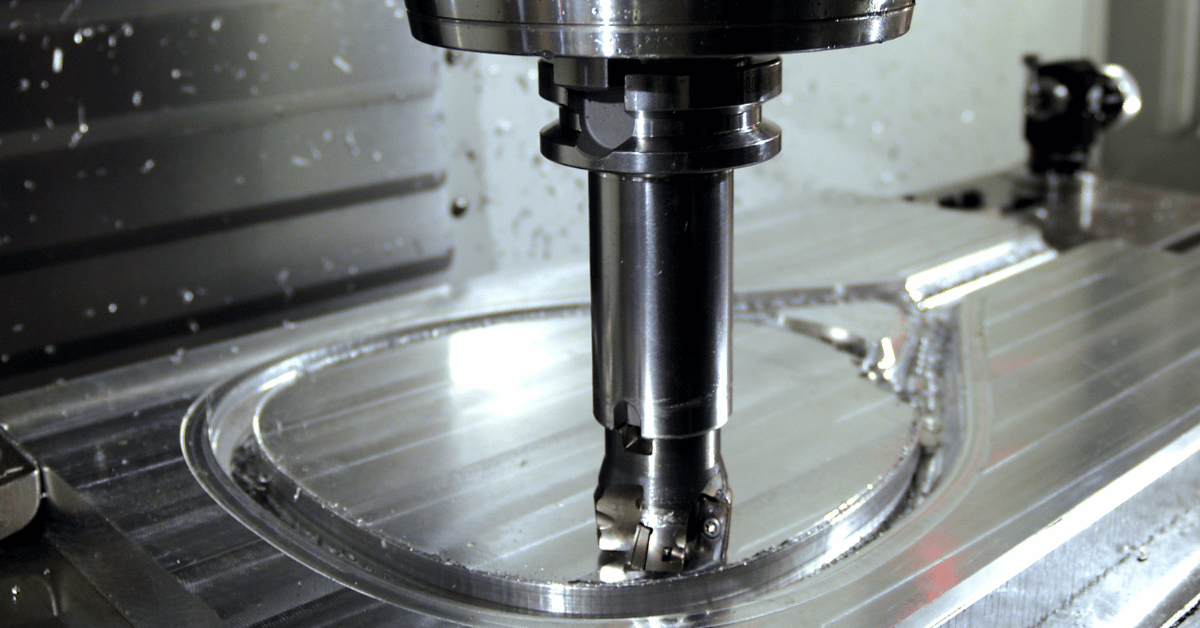

Sheet Metal Cutting

The Stripper. The stripper performs two vital functions during the punching process. The most obvious is to hold the workpiece material against the die as the punch approaches, penetrates, and retracts. The second and less obvious function is to hold the punch tip rigid as it punches the hole in the workpiece. The Die.

and Fig. 10 illustrate the relation between the punchdie clearance and... Download Scientific

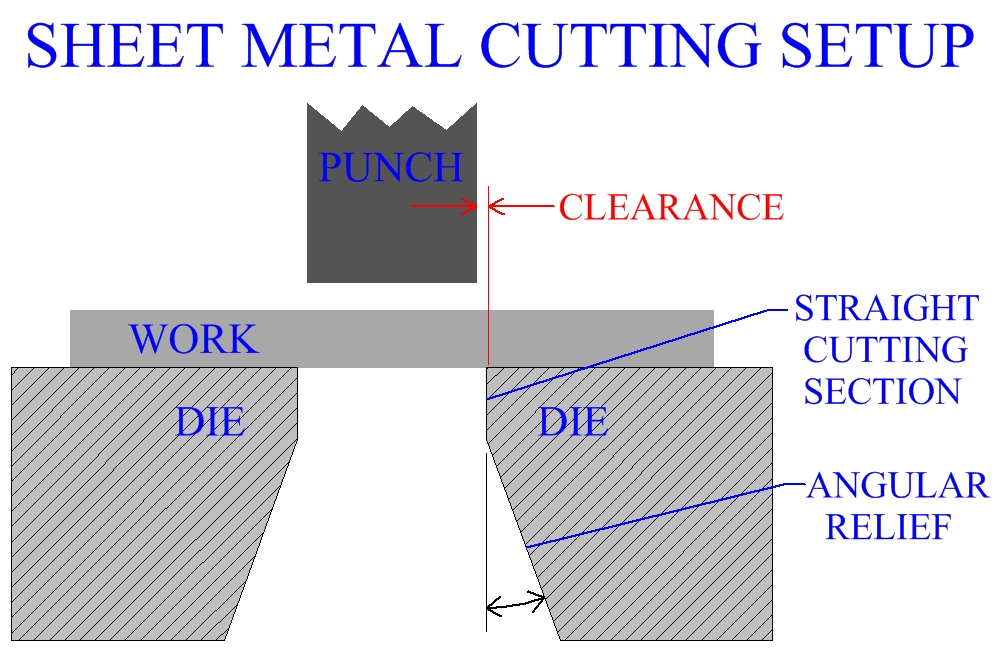

Online Die Clearance Calculator Tool. Clearance is the amount of extra space required in the hole of the die to allow the punch to pass through to punch a hole in the material. Clearance is determined by the type and thickness of the material being punched. Determine proper clearance by using this Die Clearance Calculator.

Sheet Metal Cutting

Square corners cause problems with galling on the punch and cracking in the die. It never seems to fail, the punch galls, then the die cracks from the material build up. A radius or chamfer will extend the life of the tooling by 25%. Remember, the radius or chamfer in the die follows the same clearance as the rest of the punch.

Two types of components of punch and die for circular holes Download Scientific Diagram

Clearance is determined by the type and thickness of the material being punched. Determine proper clearance by using these guidelines or click the button below and we'll calculate it for you. Example: a 9/16" punch punching through 1/2" thick mild steel would need 1/16" clearance. The die size would be 5/8". When ordering dies, refer to our die.

Punch And Die Clearance

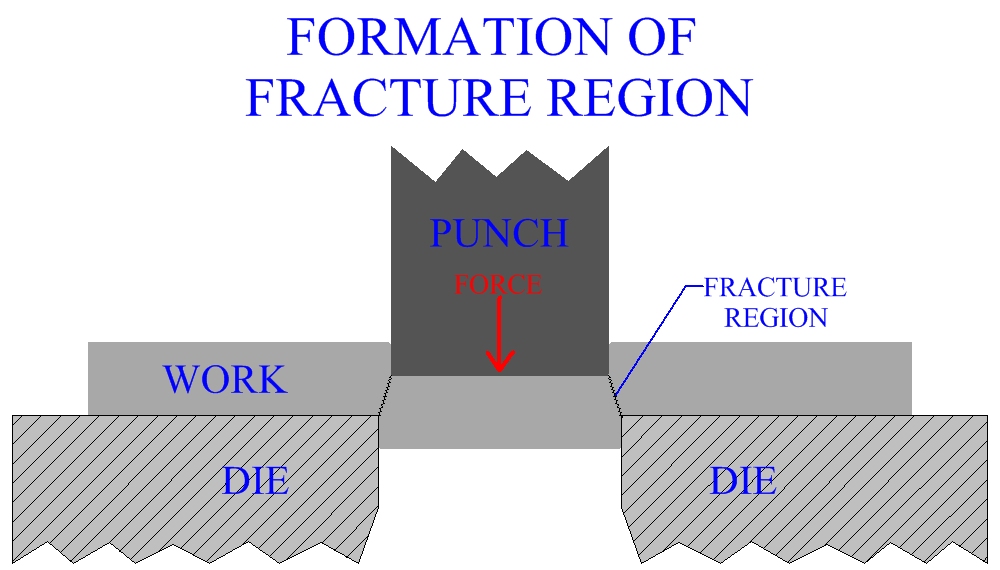

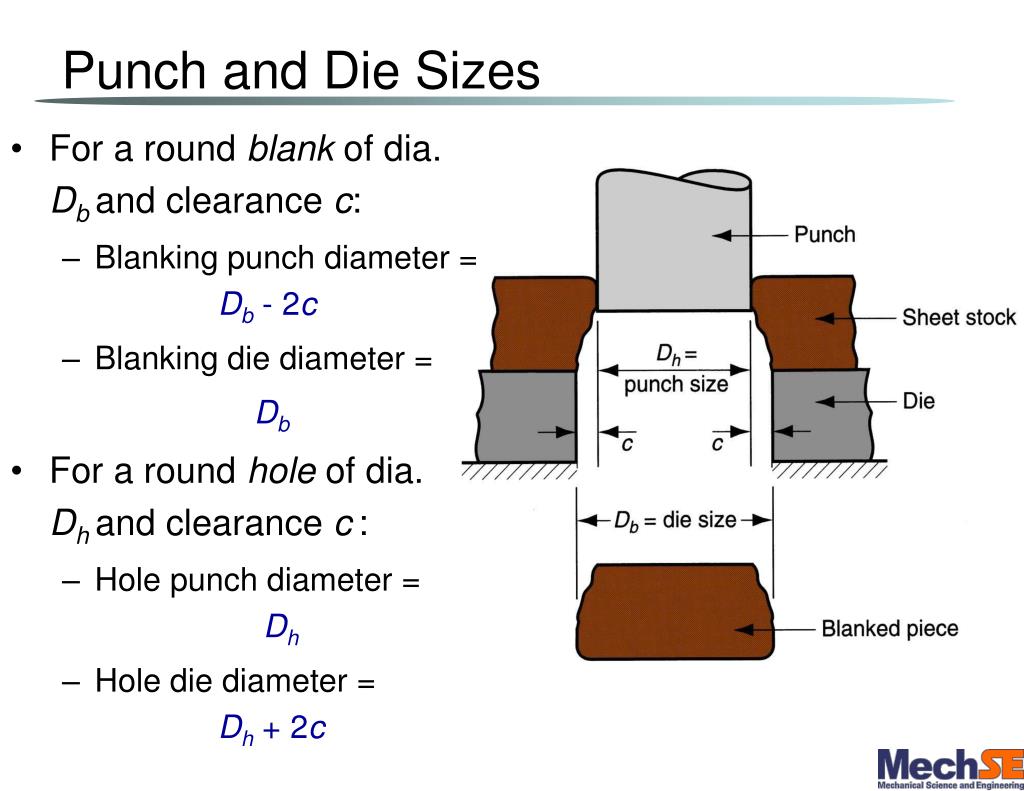

4. Determination of clearance value. 1. Definitions. The cross-sectional area of the punch in a blanking die is typically smaller than the size of the die hole. There is a specific space, known as the clearance, between the punch and the die. This can be seen in the illustration below. 2.

Punch And Die Clearance

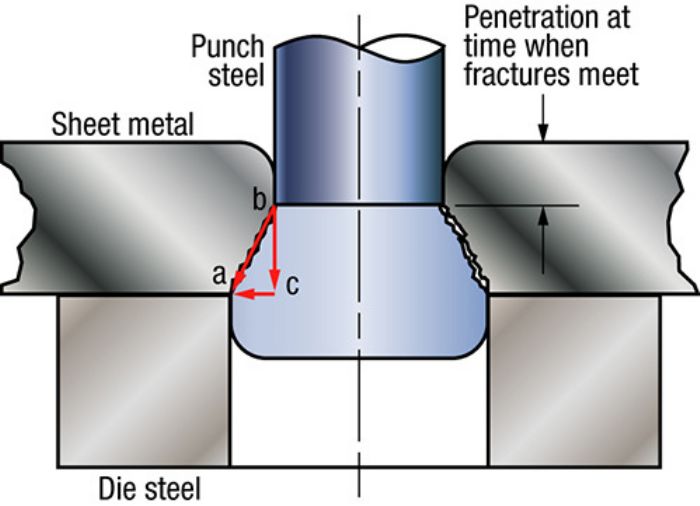

Press Dies Tutorial. Clearance is the gap between the punch and the die as shown in Fig. 1. If the clearance becomes large, although the force necessary for blanking will be small, the shear droop of the cut cross-section and the inclination of the fracture cross-section shown in Fig. 2 both become large. The clearance values of the blanking.

Understanding Horizontal Forces in Stamping Dies MetalForming Magazine Article

How to Estimate Die Clearance Required for Punching Aluminum Formula: MATERIAL THICKNESS X .15 Example: .250 x .15 = .0375 How to Estimate Die Clearance Required for Punching Mild Steel Formula: MATERIAL THICKNESS X .2 Example: .250 x .2 = .050 How to Estimate Die Clearance Required for Punching Stainless Steel Formula: MATERIAL THICKNESS X .25 Example: .060 x .25 =. Continue reading Die.

General Punching Information Cleveland Steel Tool

The punching clearance refers to the gap between the punch and the die (see Figure 2-7). Unless otherwise specified, it generally denotes the total clearance on both sides. The punching clearance not only significantly affects the quality of the punched parts but also impacts the die life, punching force, stripping force, and ejection force.

PPT ME 350 Lecture 18 Chapter 20 PowerPoint Presentation, free download ID1375744

Therefore, in the design of deep drawing dies, the clearance on each side between the punch and die is generally greater than the material thickness to reduce friction. The formula for calculating the clearance z/2 on each side is: z 2 = t m a x + K t. In the formula, "t max " represents the maximum thickness of the material (mm);

Punch And Die Clearance Calculation Knowledge Base Swallow Machinery Converting Industry

The die clearance refers to the distance between the punch and die in a mold, which significantly influences the mold's performance and the quality of the workpiece. Adjusting and controlling the die clearance is a critical aspect of mold manufacturing and maintenance. Firstly, there are several methods for adjusting the die clearance.

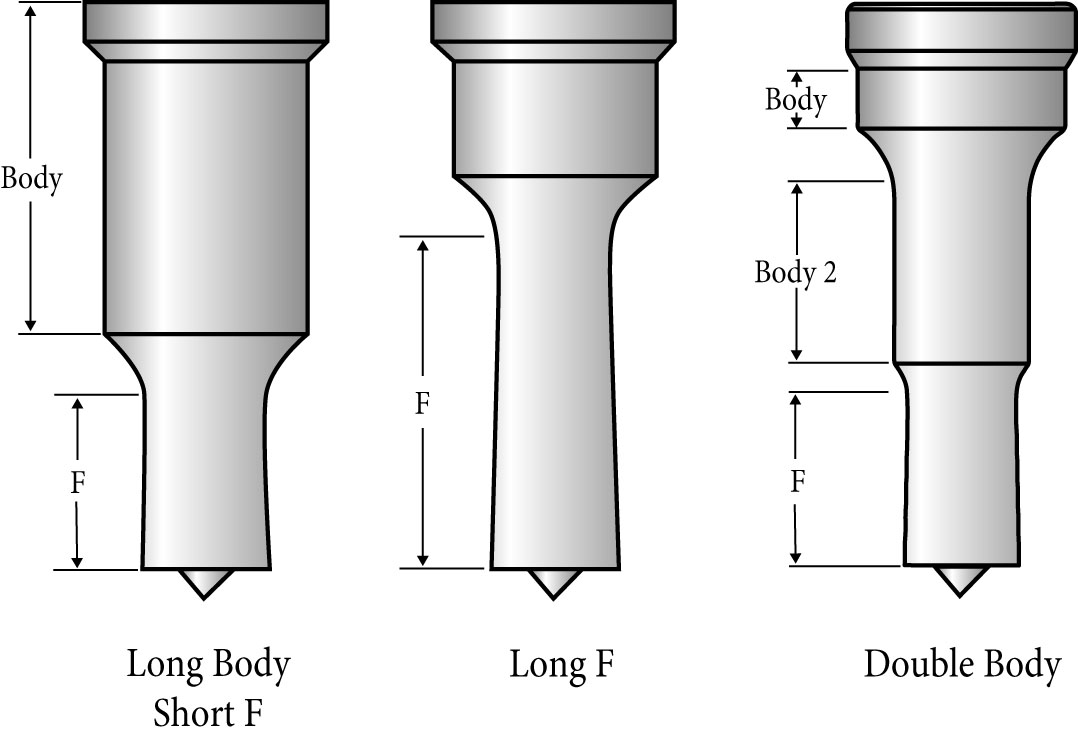

Special Lengths on Standard Punches Cleveland Steel Tool

Jektole clearance can range from 2.5% to 20% or more. The correct Jektole clearance depends on stock tensile strength and thickness, punch size, and other parameters. The Die Clearance Calculator can determine die clearance according to a proprietary database containing over 2000 clearance tests. Each test result was recorded and a mathematical.

Press Brake Toolings, A Guide to Punches and Dies Selmach™

Selection of die clearance should be based upon the type and thickness of material to be punched. Incorrect selection of die clearance can cause the following problems: • If clearance is too small, tool wear will increase and galling may result. • If clearance is too big, slug pulling may result including excessive burrs.

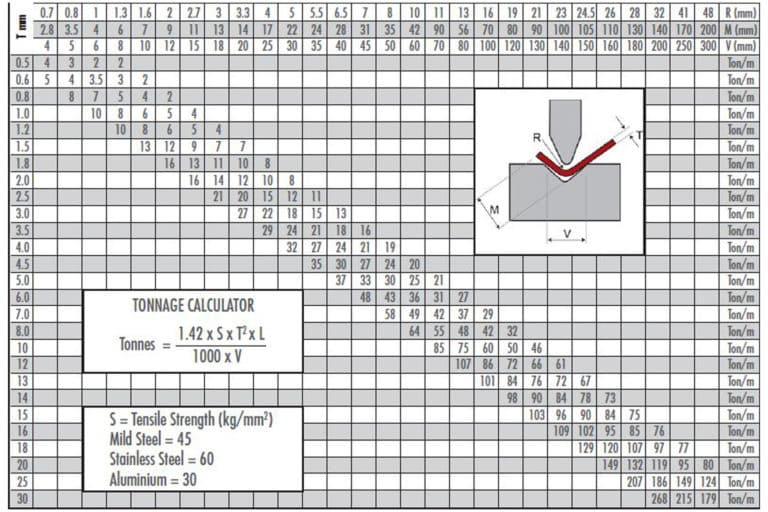

ac tonnage calculation formula

Defining Die Clearance. Die clearance is the gap between the punch and the die where the actual punching of the material takes place. It's measured by a specific formula, which depends on the material's thickness and a clearance factor determined by tooling manufacturers. Understanding the Die Clearance Calculator

How does a punch and die actually work? ADDLER

Die clearance, typically expressed as a percentage per side, is the distance between a punch's cutting edge and a die button's cutting edge. It's the amount of extra space that's needed to provide the leverage to shear and break the stock material to create a hole. The percentage per side relates to the thickness of the workpiece material.

and Fig. 10 illustrate the relation between the punchdie clearance and... Download Scientific

The proper and safe clearance between the punch and the die will be different based on the size of hole you are punching, the material thickness, and the material hardness. Use this tool to help determine the correct die size based on the suggested minimal die clearance. Also See Our Punch Tonnage Calculator.

Punching Tools dittmanntools

You can estimate proper die clearance with a die clearance calculator. To optimize the die clearance, inspect the slug and hole. To correct an unacceptable burr on the die side of the hole requires tighter clearance. Looking at the side of the punch slug, the top 1/3 should be sheared and burnished and equal to the size of the punch; the.

.